Unidose

A dose every

40

secondes

Set-up time less than

3

minutes

Filling accuracy is around

20

µl

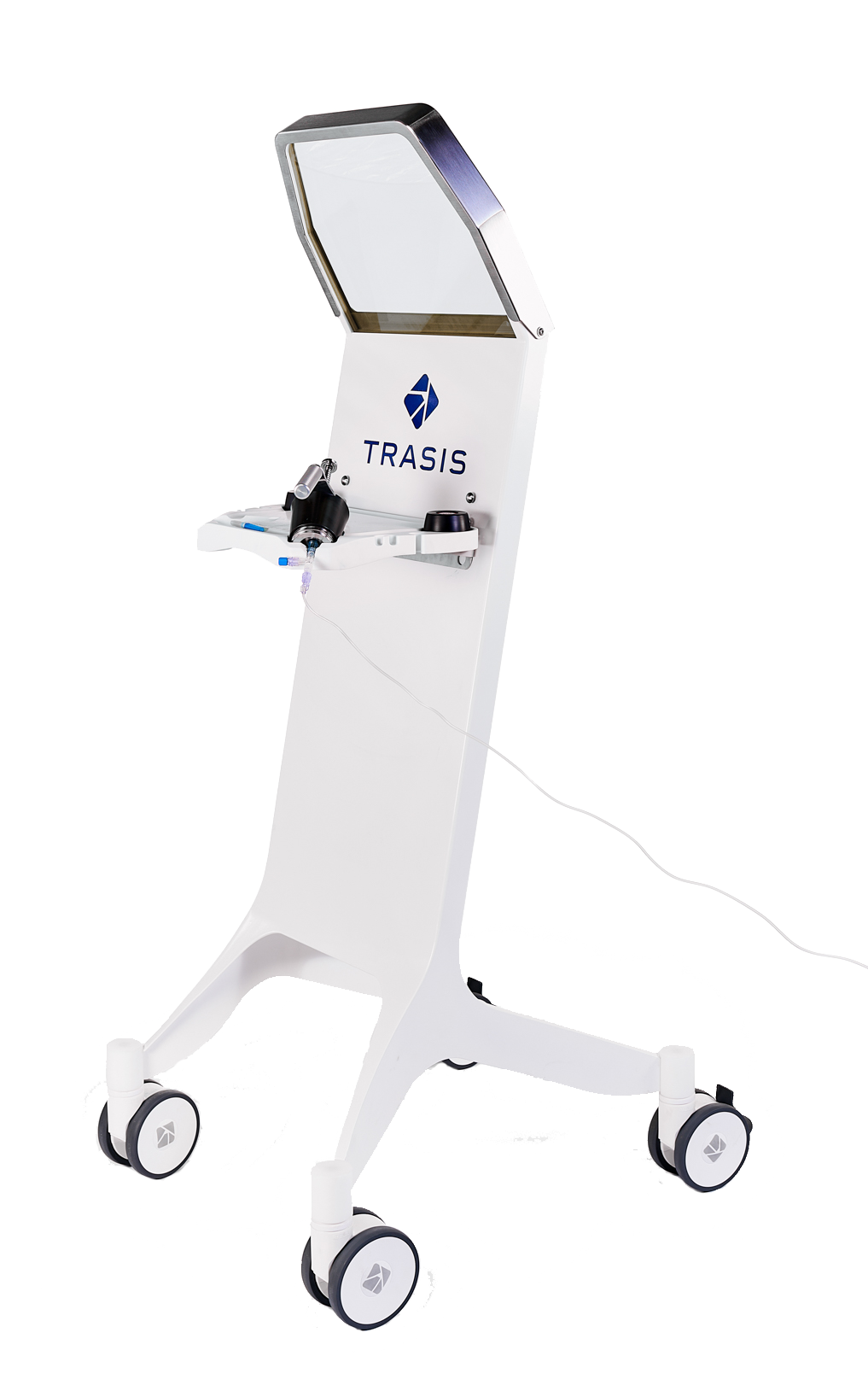

Unidose is a one-stop solution for the dispensing and injection needs in your nuclear medicine department.

Are you looking for a cost-effective and reliable automatic filling machine for your hospital practice? Are speed and safety paramount? Unidose is a one-stop solution for your nuclear medicine department. Unidose serves all your dispensing and injection needs, offering an automated filling system that covers all aspects of dose preparation and patient injection. It comes complete with an ergonomic hot cell, ready-to-use consumables, a dose tungsten shield and a mobile radiation protection screen. Take the worry out of dose preparation, providing your operators with more time to focus on what really matters: patient care.

Automate your preparation of PET radiopharmaceuticals

Preparing one or several patient doses at once with the Unidose dispenser allow you saving substantial time and reducing drastically the exposure of operators. The Unidose dispenser automatically divides your bulk of a radiopharmaceuticals into patient doses ready to be injected. Both the activity and the weight are measured, ensuring an extremely accurate preparation of the patient doses. This system can dispense a broad range of tracers and preparations, with full traceability and in compliance with pharmaceutical standards and regulations.

Quickly prepare the radiopharmaceutical doses ready to be injected to patients

Keep everything under control

Reduce staff radiation exposure by up to 95%

Go for an all-included solution for your day-to-day hospital practice

Tech Specs

Brochures

Trasis strenght : Our dedicated customer support

As with every area of our business, we take customer service seriously and, as always, excellence is our No.1 priority.